SMART DREDGING

SMART DREDGING® consists of a specific set of sensors, scanners and controlling components. They provide plenty of information to the suction dredger operators. Thanks to iteration calculations performed every second, we are able to increase the efficiency of bottom sediments dredging by 50 % in comparison to regular suction dredgers. How were we able to achieve this?

SMART DREDGING includes an induction flow meter and two abrasion-resistant manometers. The system calculates hydraulic performance delivered into the pumped hydromixture from the recorded data every second. We also monitor pressure to prevent vacuum cavitation. The dredger operator thus gets clear information about the performance leeway available to ensure maximum flow without blockage of the pipeline. As a result we get higher volume of solid particles in the hydromixture. Therefore we reach higher amount of the dredged sediment with the same amount of pumped suspension.

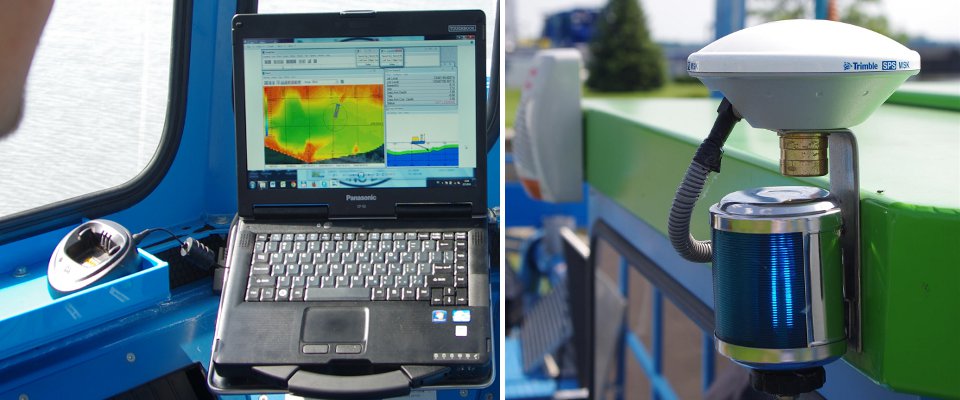

The certified software DREDGEPACK® is used to monitor sectors and depths intended for dredging. With a set of position sensors, it can determine a GPS location of the dredger with a precision of 20 cm. Moreover it can also determine the position (including depth) of the cutter head of the suction dredger. Therefore, if there is a localized area with limited dredging possibility (due to ecological or economic reasons) in the water body in revitalisation. Hence the SMART DREDGING system can avoid this area with a high level of precision.

Technical details:

- Total number of sensors: 7

- Link with the DESET technology: WiFi link

- Graphic output: 3D map of the dredged area

- Automated pumping station control to increase the hauling distance

- Back-up of all operational data